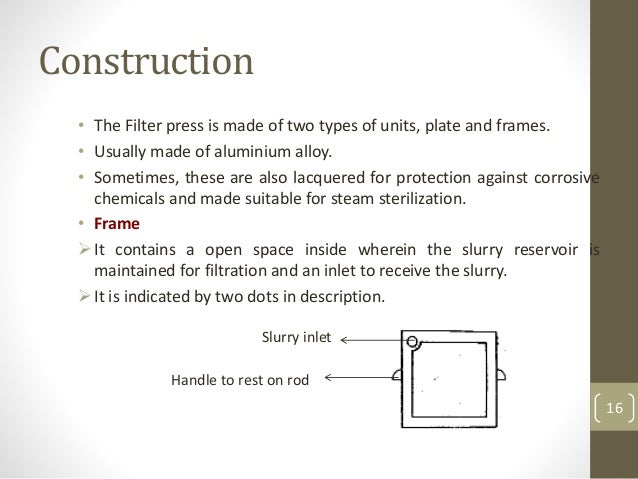

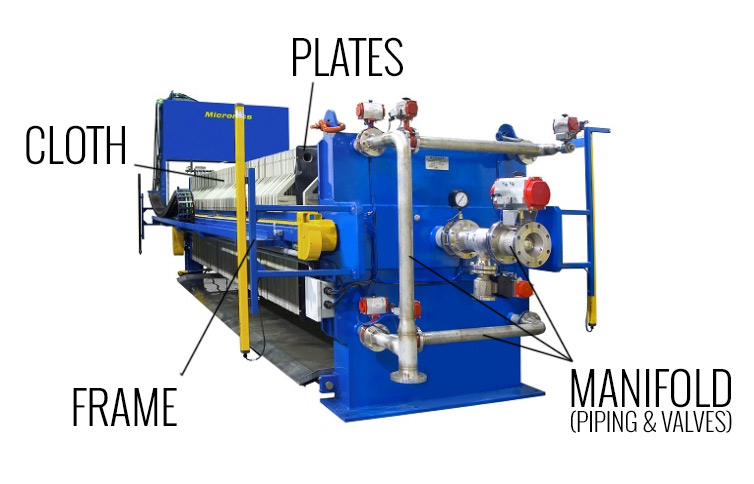

A plate and frame filter press is the most fundamental design and may be referred to as a membrane plate filter this type of filter press consists of many alternating plates and frames assembled with the supports of a pair of rails with filter membranes inserted between each.

Construction and working of plate and frame filter press.

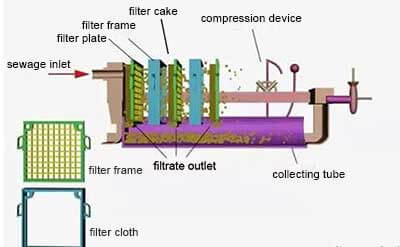

When working the slurry will be transferred by feeding pump from the feeding hole on the thrust plate to all chambers under the pressure of feeding pump solid particles in the slurry will be trapped into the filter chambers and form into filter cakes slowly liquid through out the filter clothes and come out of outlet holes.

Plate and frame filter press.

The filter press arranges the filter plates and the filter frames in parallel and alternately and the filter cloth is clamped between the filter plate and the filter frame in each group.

And a filter cloth is sandwiched and pressed between each filter plate and filter frame to form a filter chamber.

Once the filter chambers are loaded with slurry the plates are forced together with hydraulic rams that generate pressures typically in the region of 100 pounds per square inch 70 000kg per m2.

This type of filter is widely used in the food pharmaceutical brewing and distilling industries.

Plate and frame filter presses recessed plate and frame filter presses membrane filter presses and fully automatic filter presses.

A filter press consists of a series of chambers containing square or rectangular filter plates supported in a frame.

For comparison a car tyre would be inflated to around 30 pounds per square inch.

A small plate pack mounted on a stainless steel framework enabling demonstration of filler operation.

Working principle and application of plate and frame filter press.

The laboratory size unit is robust and versatile.

This clamping is done by either an old style wheel crank or more modernly with a hydraulic pump and cylinder either manual or automatic.

Filter presses can be built in a wide range of sizes from small lab scale 150 mm presses to those with much larger capacities such as those with 1500 and 2000 mm filter plates.

The main part of plate and frame filter press is a set of filter chambers consist by filter plates and filter frames in alternating order.

Ft14 plate and frame filter press.

Plate and frame filter press is the old filter press model and also all the other filter press design and construction basic model all the other filter press model such as recessed plate filter press and membrane filter press are designed based on this filter press based on the plate and frame filter press working theory all the special designed functions of the filter press are innovated and full automatic filter press start to work in different industries.

The design is a skeleton made of metal that holds and clamps the filter plates together to form a pressure chamber.

Plate frame filter press is a mature dewatering equipment which is widely used in sludge dewatering projects in europe and america.

Each plate is covered by a material or membrane that acts as the initial filter when the press is in.