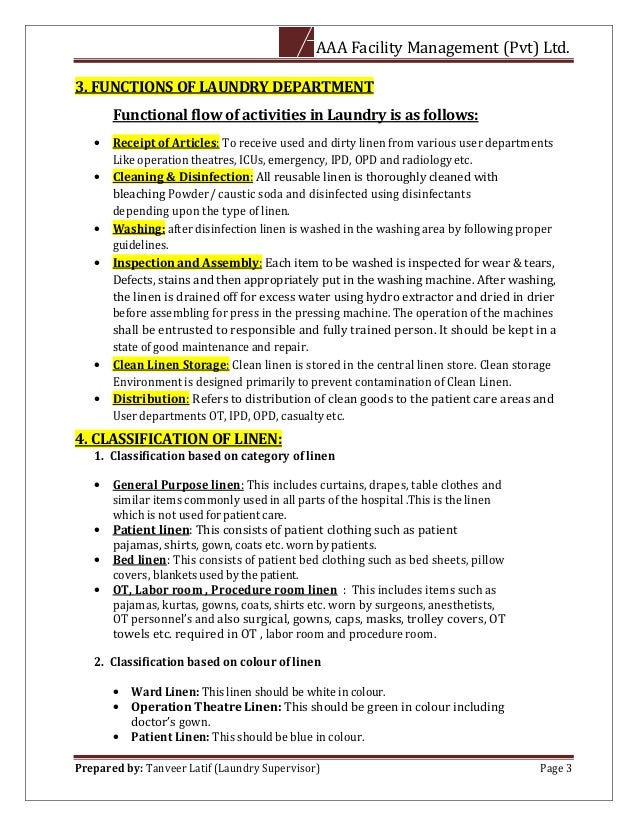

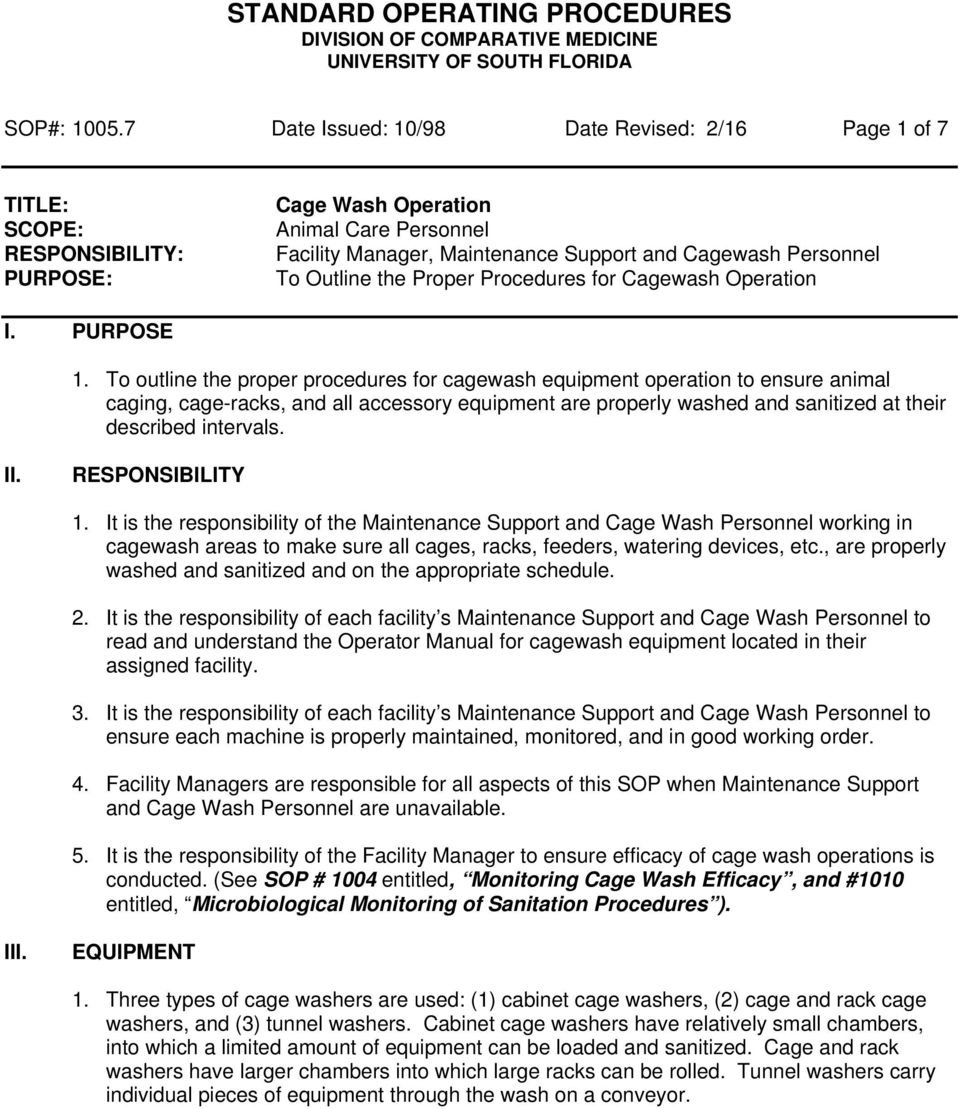

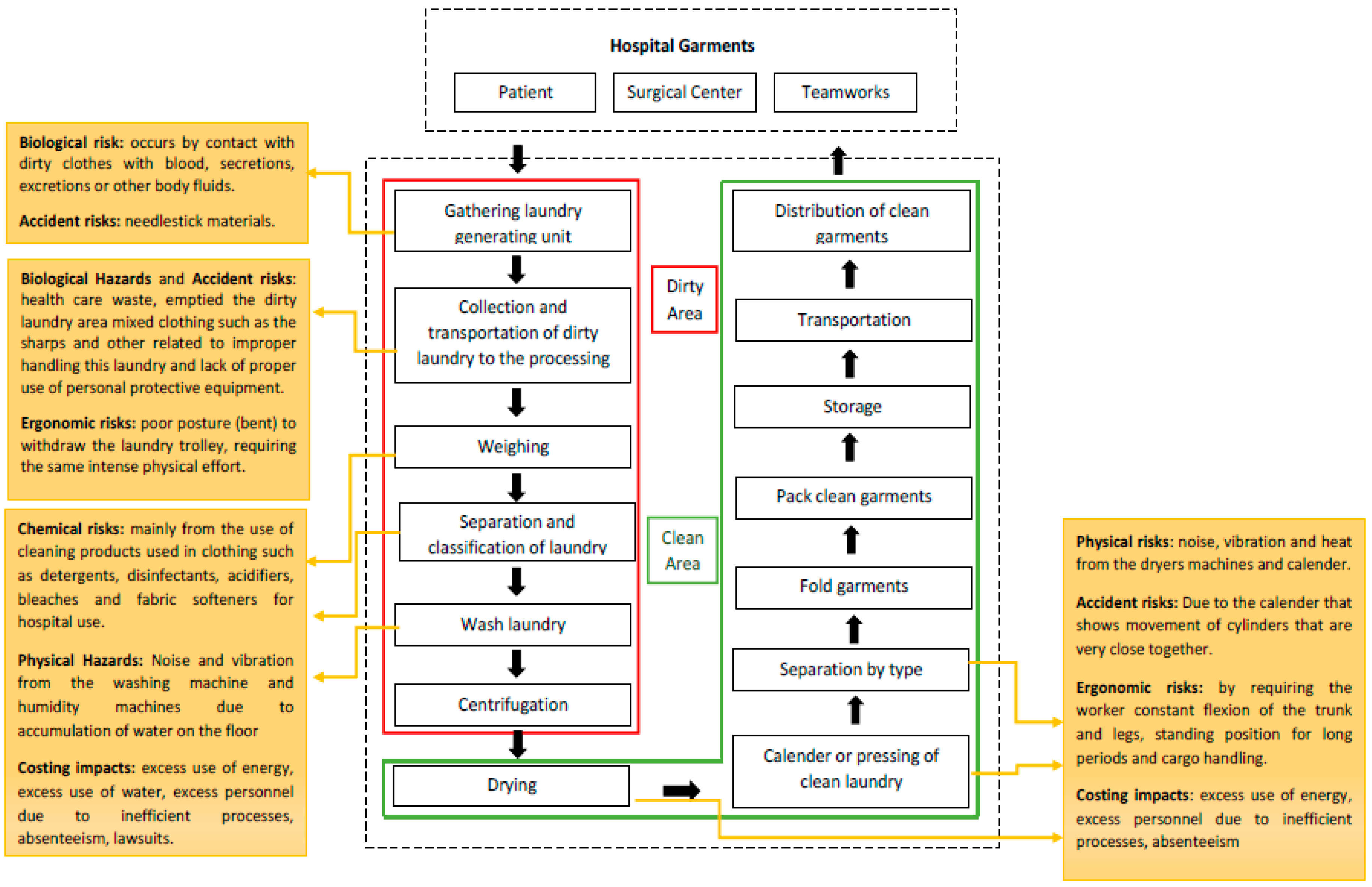

The standard operating procedures for your laundry reflect the unique challenges you face in receiving and handling soiled linen and processing it into clean linen.

Commercial laundry standard operating procedures.

The director of services must inspect the laundry for cleanliness each day.

2 0 application this guidance applies to.

Laundry standard operating procedures and work instructions laundry operation flow chart laundry organisation flow chart laundry operation procedures slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising.

Kitchen rags require special handling.

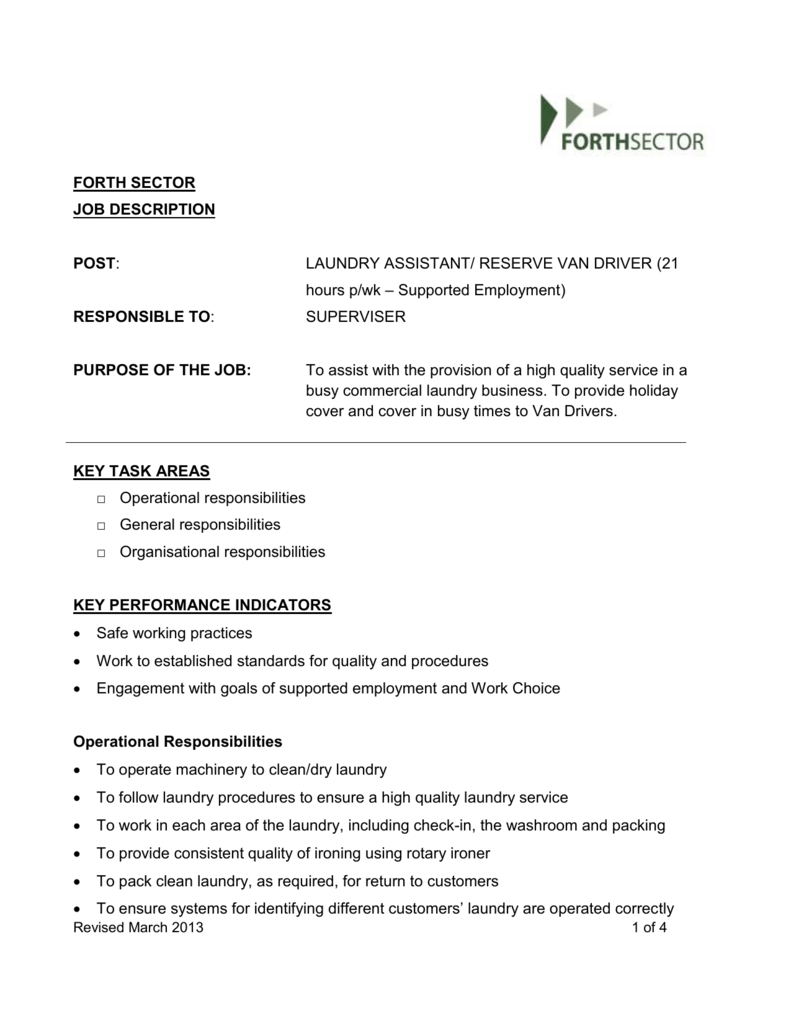

Laundry sop standard operating procedure for loading and unload washers in hotels 1 prepare loads for washing 2 organize the laundry activity 3 special thinks to notice while laundering linens and uniforms.

Sop laundry loading washers.

Laundries that have management solutions embedded in their.

Despite that scale.

While most commercial laundry plants are at least 30 000 square feet some can be larger.

All line traps are to be emptied frequently.

A complete laundry clean up and blow down must be conducted each day.

Improve personnel processes that are lagging and eliminate those that don t work.

Using laundry business management software to set standard operating procedures optimise equipment run times for effortless efficiency.

A laundry manager can face administration challenges that deal with expensive equipment breakdowns implementing a linen management program or dealing with rising cotton prices and reducing operating costs.

Laundry must be kept free of dust and inspected daily.

Bags for segregation of linen at the user departments safe handling of used linen linen must be handled and segregated as follows in different color coded bags colour linen type for non contamination for contamination linen for infected linen.

The purpose of this environmental standard operating procedure esop is to provide environmental guidelines for performing industrial laundry activities.